Our Capabilities

Empowering Your Vision Through Expertise

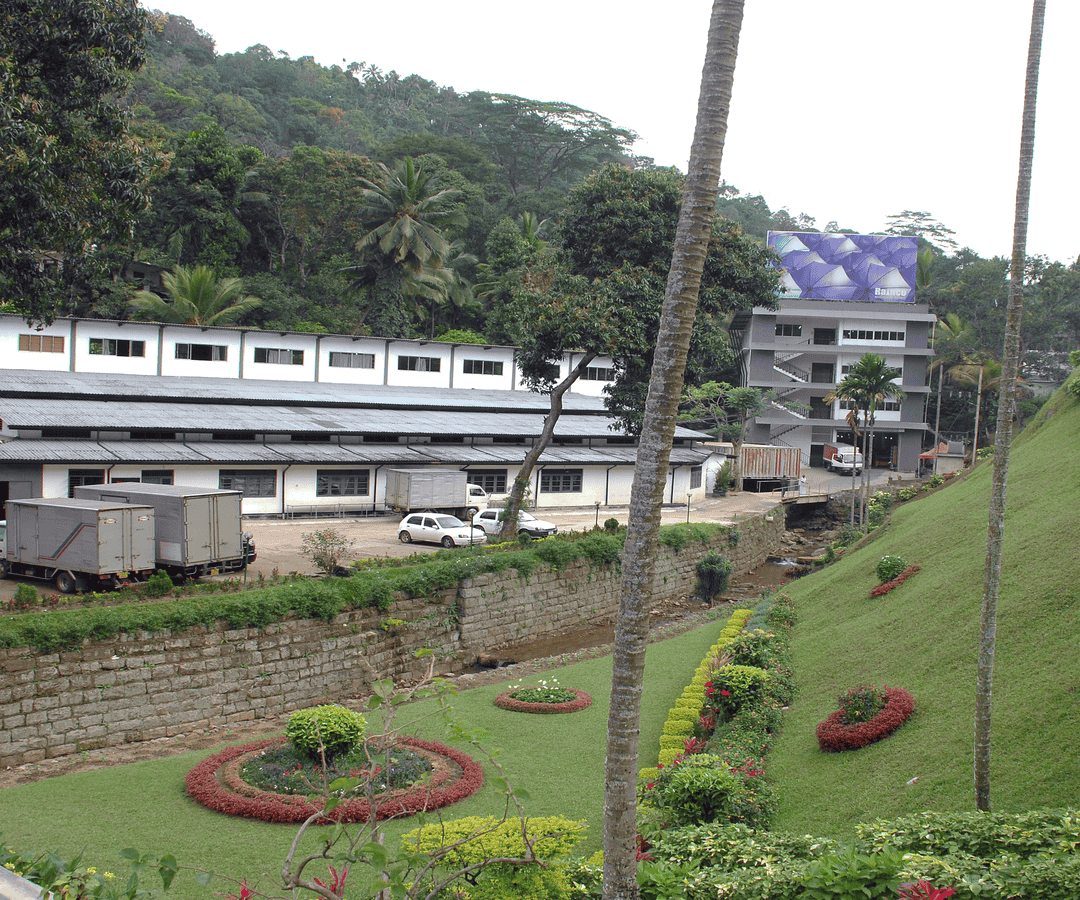

Manufacturing Plants

Efficiency at Every Production Stage

Our four manufacturing plants, including two export-oriented facilities, have a production capacity of 24,000 units daily and 8 million units annually. We strictly adhere to global social and welfare standards, with a firm prohibition on child labor, fixed 8-hour workdays, and a commitment to diversity. Strategically designed to optimize production efficiency while maintaining high-quality standards, these facilities enable us to meet the growing demands of the global market while fulfilling the innovative visions of our customers.

Our Process

Efficiency at Every Production Stage

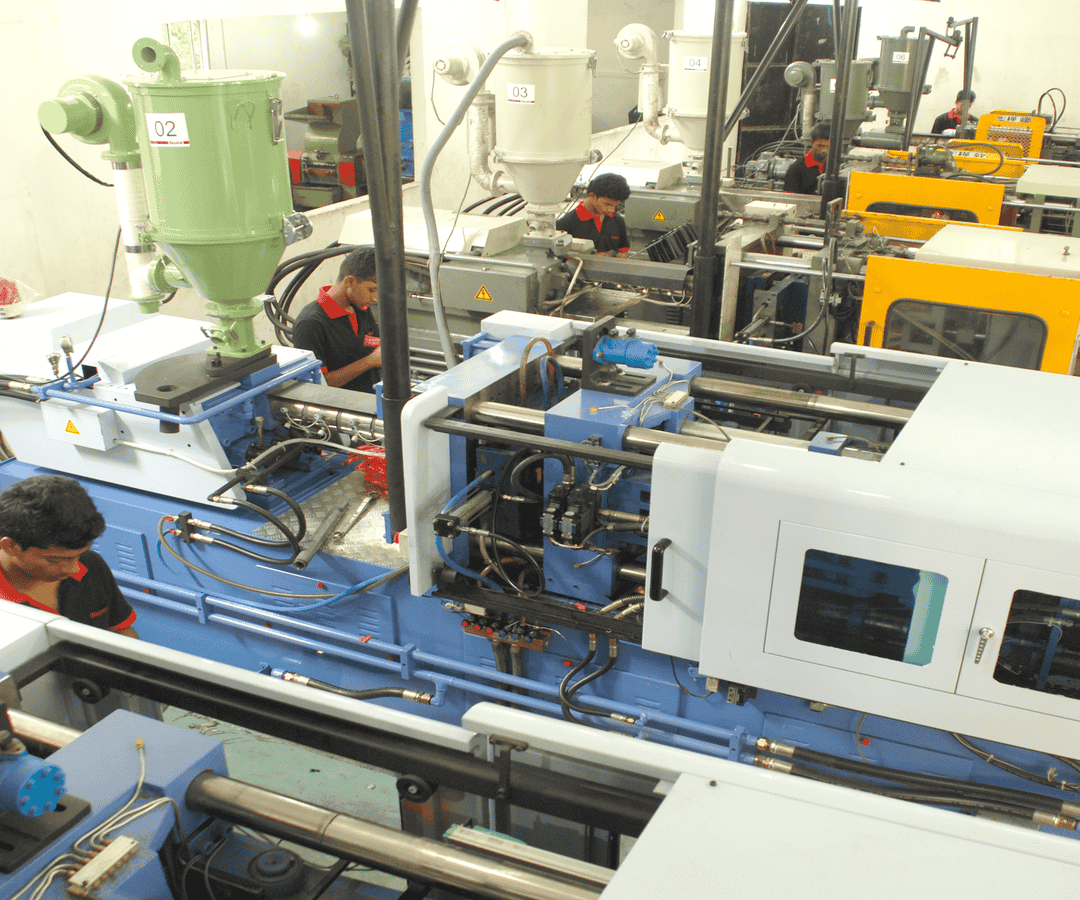

Our Technology

Tailored Solutions Through Cutting-Edge Technology

Research & Development

Committed to Innovate and Evolve

Quality Assurance

Excellence Is in the Details

Our quality assurance process combines standardized testing protocols with proprietary in-house methodologies, ensuring our products meet the highest standards. Our commitment to quality is further reflected in AQL standards and photography umbrella testing methods, guaranteeing excellence in every product. Leveraging our experience with global leaders, we have developed unique testing methods, providing a competitive edge that sets us apart.

- Water proof test

- Water repellency testing

- Salt spray test

- 3rd party testing

- Fabric (4 point system) checking machines

- Slitting machine (with fabric checking)

- Fabric visual inspection

- Thread strength checking equipment

- MOC testing machines

- AOC testing machines

- Wind resistance checking

- Color fastness testing

- GS Standards – Germany

- ES Standards – Europe